In many industries, awareness of the importance of sustainability is rapidly expanding. The textile industry is one of them. To put it another way, we aim to provide the quantity to industry without sacrificing quality. In the past, sustainability was almost invariably associated with its cost. Therefore, often people ignore pricey sustainable alternatives.

Today, the environment is more prominent in people’s minds; the market expects higher levels of long-term sustainability for future generations. Sublimation printing is a response to this new yet urgent demand in the textile industry. In this article, we will see what sublimation printing is and its need.

- Overview of Sublimation Printing

- Differentiating Inkjet and Sublimation Printing

- How Does Sublimation Printing Work?

- Kinds Of Sublimation Printing/Inks

- Types Of Equipment Required For Sublimation Printing

- Applications Of Sublimation Printing

- Dye-Sublimation Thermal Printer Print Speed

- Why Use A Sublimation Printer?

- Limitations:

- Pre-Requites For Sublimation Printing

- Bottom Lines

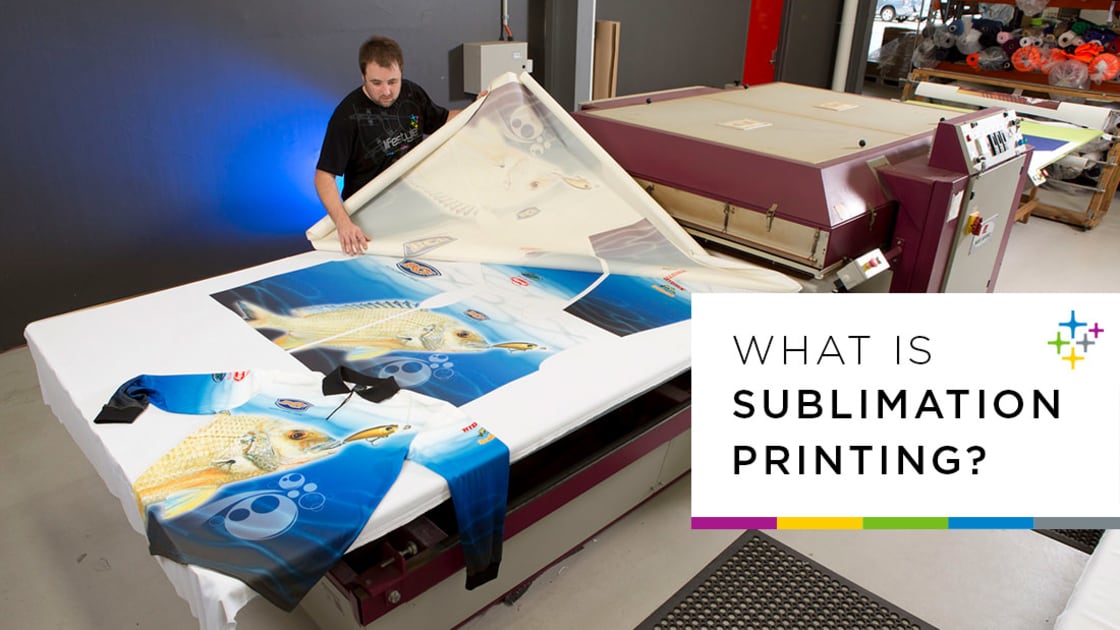

Overview of Sublimation Printing

The use of sublimation printing is growing in popularity. It’s a type of digital printing that employs the use of customized paper. The dye sublimation method creates brilliant, long-lasting images on the best-designed graphic apparel, home decor, and advertising displays.

However, sublimation does not work well on cotton. Alternatively, silk or most natural textiles can be used. Sublimation printing works well for t-shirts, hoodies, and socks, as long as they include a high percentage of polyester. Therefore, we need a sublimation printer instead of an inkjet printer to print for designs.

Differentiating Inkjet and Sublimation Printing

Inkjet printing

It works by spraying microscopic ink particles onto paper. As the print head nozzle of the Canon inkjet printer heats up, it creates bubbles, which help the ink spread out. As a result of this technology, ink can be placed on the paper surface in precise shapes and at exact points in space. Printing can be done on various papers, including general printing paper, postcards, glossy paper, etc.

Sublimation-printing

This printer uses thermal transfer technology.

It uses a print head to generate heat, which causes the color ink to be vaporized and transferred to a specially coated sheet of paper (sublimation*). Heat control allows printing density to be adjusted in small increments, resulting in smooth gradations.

How Does Sublimation Printing Work?

Sublimation printing involves infusing the image directly onto the printing paper, resulting in a minimal mess and a quick and easy process. The picture is then transferred from the sublimation paper to the item using heat.

Businesses and home designers use this type of printing to create graphics for apparel, signage, house decorations, company exhibits, and personal goods like coasters, coffee mugs, and key chains.

Kinds Of Sublimation Printing/Inks

Two types of Standard dye sublimation inks used in sublimation printers are;

Aqueous sublimation ink

Type of sublimation ink is used in desktop and large-size printers, which is the most popular.

Solvent dye sublimation ink,

Applicable in xaar spectra.

Types Of Equipment Required For Sublimation Printing

1. Printer For Dye Sublimation

First and foremost, a sublimation ink printer would be essential. It is used in both households and factories. These sublimation machines would have cost a lot of money just a few years ago. These printers have become much less expensive as the demand for printed products has increased.

2. Paper for Sublimation

Any spectrum color can be made and transferred onto paper suited for the machine using the sublimation printer. Sublimation or transfer paper is the name for this sort of paper. Like office paper, one can print a personal work of art, a personalized logo, a family photo, or any other design wanted for usage on the paper.

3. RIP Software and a Computer

Some sublimation printers come with software for configuring what will be printed. RIP software stands for Raster Image Processor. Software must be compatible with the printer being utilized.

4. A Cutting tool

Cutting equipment, whether it’s a knife or a rotary blade, is also advised for sublimation. When making unique fabric goods, this is a must. Some cutting products have multiple options in one system to meet a variety of purposes. Hemming the material would also necessitate the use of a sewing machine. It is essential when working with SEG (Silicone Edge Graphic) frames.

5. A Heat Press

After printing, a heat press is also essential. Coffee mugs, t-shirts, and tablecloths can all be customized using a heat press. Due to the improved picture quality, the item will be durable over the long term.

There are four types of sublimation transfers in general:

Calendars Thermal Press

This type of heat press is used when sublimation printing on a softer material that is larger, such as fabric. This press is enormous and can print on clothing and banners.

Heat Presses For Small Areas.

Sublimation of small items, such as kitchenware, a small heat press is recommended.

Infrared Heat Press On A Flatbed

Using a flatbed heat press is recommended for sublimating more complex materials such as floor tiles and another home décor. Variable and suitable for printing on apparel, this type of press is highly versatile.

Infrared Heat Press in Three Dimensions

According to the manufacturer, a 3D vacuum heat press is the way to go for smaller objects with more complex shapes and edges. Because this machine was designed to sublimate on non-flat surfaces, many products can now be printed.

Applications Of Sublimation Printing

The following are some of the applications of sublimation printing:

Textile

Polyester sublimation is explicitly done by using the sublimation printing method. Polyester fabrics are transformed into magnificent carpet fabrics, flagging material, sails, and sportswear when printed with diverse inks. Even after a lot of use, they’re all washable and long-lasting. Polyester Fabrics are one of the most used dye sublimation materials. There are two types of them:

Knit

Polyester products such as garments, flags, banners, and custom printed table cover hang and flow in their natural habitat.

Woven

Bespoke tote bags, cloth backdrops, and custom tents are examples of knitted items.

Hardware

Sublimation prints can be utilized on mugs, key chains, magnets, and other ceramic, wood, and metal items to decorate and create signage for businesses. The goods are printed with vibrant inks that keep their appearance even after several things of washing. It is simple to sublimate synthetic materials using a polyester foundation.

Dye-Sublimation Thermal Printer Print Speed

Because sublimation thermal printers use heat to transfer the dye onto the print media, the printing speed depends on how the thermal parts change temperatures. The print time differs between dye-sublimation printers.

- A low-cost home-use dye-sub printer can print photos in 45 seconds to 90 seconds.

- More powerful printers can print much faster, i.e., photos in 6.8 seconds.

Why Use A Sublimation Printer?

- Dye sublimation creates a better-looking image that can be used for years, despite being more expensive than heat transfer printing.

- As a result, there is more room for innovation than with other printing procedures that are more affordable.

- If you’re finding something for a short period, heat transfer is a good option. In contrast, dye sublimation is the best option if you’re printing something, especially sublimation clothing. It will be kept for a long time and will be washed.

Limitations:

- Because sublimation inks are transparent due to their inherent composition, it is suitable for light-colored and white backgrounds and objects.

- Another drawback of sublimation printing is that it doesn’t work well with materials made entirely of cotton and non-porous surfaces without a polyester coating.

Pre-Requites For Sublimation Printing

- The fabric must be manufactured entirely of polyester or include at least 2/3 polyester.

- Only items with a polyester coating are ideal on non-textile substrates.

- The print area on sublimation items must be white or light-colored. It is not possible to sublimate surfaces that are black or very dark in color.

- The item’s color may fade over time if it is permanently exposed to direct sunlight for an extended period. So be careful.

Bottom Lines

In this article, we have seen the unique and advanced printing equipment, namely sublimation printing. The growth of technology also increases the importance of sublimation printing. People nowadays prefer sublimation clothing with 3D graphics over simple ones, fashioned pottery, fabrics, etc. Resultantly, it becomes clear that sublimation printing is the need of the hour, and all-over sublimation printing equipment discussed above must-have for today’s industries if they want to use sublimation printers. After reading this article, you would indeed decide which printer you should invest in while planning to purchase.